Cut To Length Line For Light Pole

Current position: Home

>

Product

Street lamp pole uncoiling production line

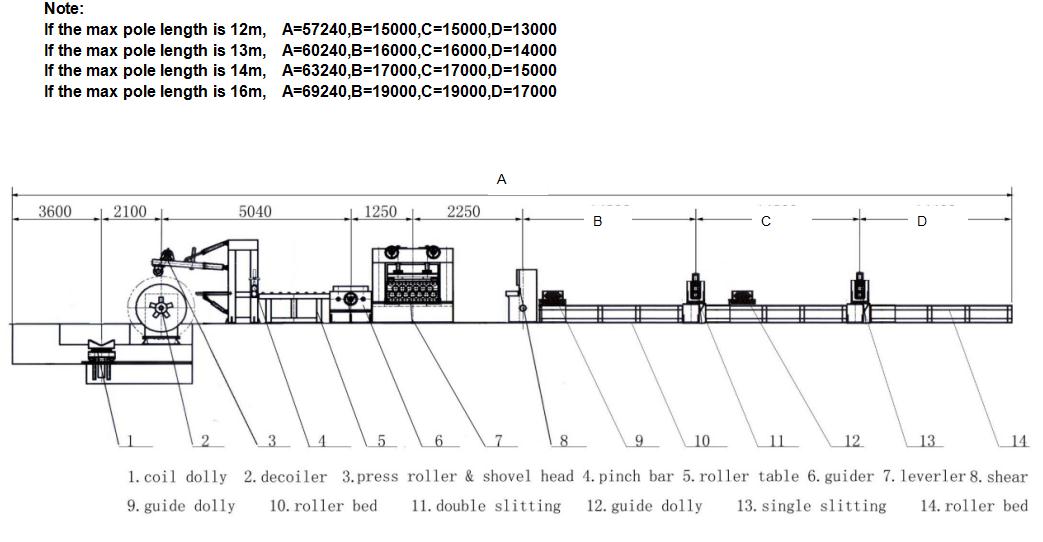

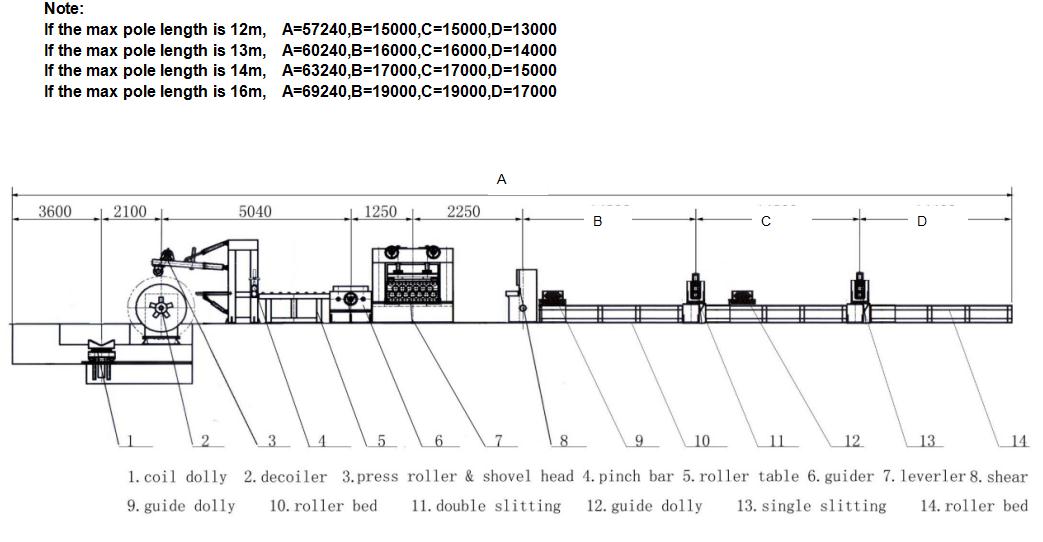

Street lamp pole uncoiling production line, model: CTLA6X1800

(Fully automatic, four-fold leveling)

Automatic type:CNC sheet length, trimming and oblique shearing, stacking belt automatic device

Application:Used for uncoiling, leveling, shearing, trimming and trapezoidal plate oblique shearing of street lamp pole materials to obtain street lamp pole plates with large head and small head

Technical parameters and production line composition

1. Material thickness: 2~6mm, Q235

2. Material width: 800-1800mm

3. Roll weight: 30ton

4. Inner diameter of coil: Φ500mm-Φ750mm

5. Leveling speed: 5- 15m/min

6. Number of rollers: 11

7. Roller diameter: 130mm

8. Length range: 2000~14000mm

9. Length tolerance: ±15mm

10. Main motor power, total power: 45kw

11. Trimming and oblique shearing speed: 15 m/min.

12. Trimming and oblique shearing machine motor power: 5.5kw

13. Trolley moving speed: 15m/min. Variable frequency adjustable, adjustable

14. Rolling shear blade material: H13k

15. Blade diameter: 280mm

16. Pinch roll diameter of skew shears: 280mm

17. Double shear inner width: 1800mm

18. Inner width of single shear: 1800mm

19. Width of the machine: 7000mm

Equipment List

1. Hydraulic loading trolley, up and down hydraulic electric horizontal movement

2. Hydraulic overhead uncoiler.

Contains both left and right

Hydraulic jacking, driven by oil cylinder to uncoil frame, can jack the coil.

Structure: body, sliding base, spindle, taper loading plate, moving cylinder.

Main function: fix coil to realize passive uncoiling. Equipped with a set of manual brake device, according to the belt tension adjustment. The transverse stroke is completed by the double-side moving cylinder. According to the width of the coil, the two cylinders can be offset left and right at the same time.

3. head strip and material guiding device

It is used to shovel the raw material of the coil and draw the plate into the traction. Hydraulic lifting, hydraulic compaction, to prevent the coil loose, and with the stripping head guide device will lead the plate into the traction roller. The power traction draws the sheet through two nip rollers, and the upper nip roller is hydraulically lifted.

Structure: guide frame, guide roller, guide motor sprocket, chain, lifting cylinder, shovel head support plate, telescopic panel, driving cylinder.

Main function: auxiliary uncoiling, feeding roller driven by motor. Assist the uncoiler to guide the plate head to the shovel plate. Then lead to the feeding nip roller, the shovel plate can be lifted up and down and stretched back and forth. During normal operation, the device is completely withdrawn from the working position.

Pinch structure: base, memorial archway, slider feed shaft, drive motor, pressure cylinder.

Main function: The sheet is sent to the rear equipment, and the transmission adopts motor cycloid pin wheel reducer and clutch. After the clamping and feeding of the sheet material is finished and the sheet material enters the leveling host machine, the clutch is disengaged, the upper roller is lifted by hydraulic pressure, and the lower roller is driven by the sheet material to rotate passively.

4. intermediate raceway

5. guide device

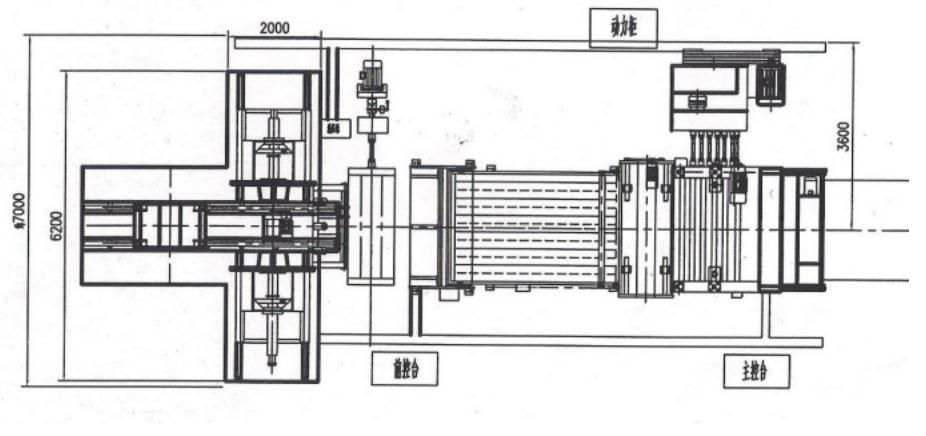

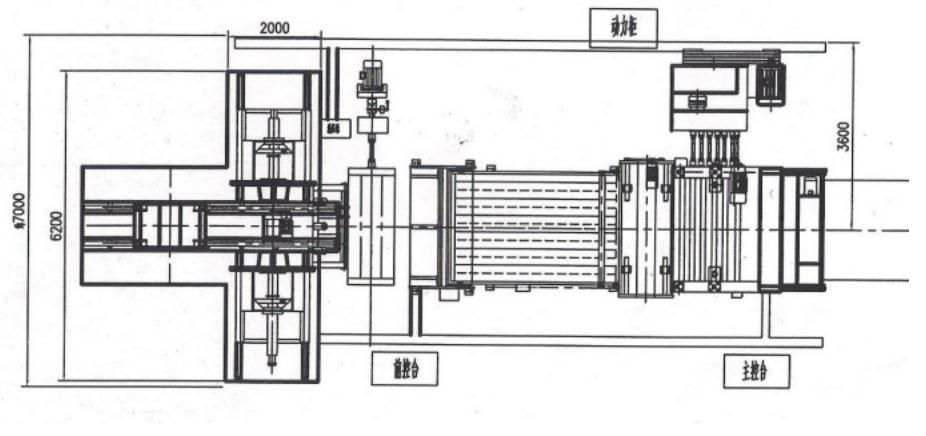

6. quadruple leveler

7. Rotary plate shearing machine

Shearing machine is a kind of equipment which is used to shear the steel plate after leveling in production line. The production line equipment QC12Y-6*2000 hydraulic swing plate shears.

The shearing machine can rotate 3 degrees relative to the center line to suit the shearing of the lamp pole sheet. The sheared plate is formed into a parallelogram, so that the plate reduces the waste of materials and is suitable for the next working procedure of a street lamp pole.

Machine structure and characteristics: steel plate welding, high strength, good stiffness, hydraulic swing on the knife, nitrogen return cylinder balance on the knife weight and return, smooth and fast movement. The lower blade is equipped with front and back fine adjustment mechanism, good blade clearance uniformity and high precision of shearing straightness. Knife gap adjustment is convenient and quick, left and right sides are synchronized, and scale value is indicated. Hydraulic pressure material, stable and gentle, pressure pad using polyurethane material, do not hurt the surface of the workpiece.

8. Row, guided trolley, automatic device to meet the length of street lamp pole

The guide trolley is in front of the double shearing machine and contains a positioning stop to ensure the consistency of blanking. At the same time, the position of the positioning stop block can be adjusted to obtain steel plates with different widths to meet the requirements of street lamp poles with different size. The guide trolley is driven by motor, which can automatically move to the required position according to the length of the street lamp pole to clamp the steel plate to control the straightness of the sheet rolling shear.

Each row roller is provided with a clutch and power. When the motor drives the roller, the steel plate is driven to move forward and automatically stops when the steel plate reaches the fixed position in front of the oblique shearing machine. and the labor intensity of operators is greatly reduced.

Both the trolley and the double shears are equipped with pneumatic positioning devices to ensure the consistency of blanking and reduce labor.

9. Plate lifting device

The unit consists of two cylinders that can be set to different positions depending on the length of the sheet.

When the sheet moves to the front of the oblique shear, after stopping, this device will raise the sheet, so that the sheet is clamped on the trolley and moved forward.

10. Double shear machine, using the principle of rolling shear, remove the hot rolled steel plate irregular waste edge, obtain the street lamp pole plate before oblique shear, accurate plate width.

It adopts the structure of two rollers and four blades. The upper and lower rollers are full thread, which is convenient to adjust the position of the rolling shear.

Double shear machine is driven by 4KW motor, and the power is transmitted to the rolling shear blade through the reducer.

With motor, gear box.

11. Row, guided trolley, automatic device to meet the length of street lamp pole

The guide trolley is in front of the oblique shearing machine and contains a positioning block to ensure the consistency of the blanking. At the same time, the position of the positioning stop block is adjusted to obtain steel plates with different inclinations to meet the requirements of street lamp poles with different taper ratios. The guide trolley is driven by motor, which can automatically move to the required position according to the length of the street lamp pole to clamp the steel plate to control the straightness of the sheet rolling shear.

Each row roller is provided with a clutch and power. When the motor drives the roller, the steel plate is driven to move forward and automatically stops when the steel plate reaches the fixed position in front of the oblique shearing machine. and the labor intensity of operators is greatly reduced.

Both the trolley and the double shears are equipped with pneumatic positioning devices to ensure the consistency of blanking and reduce labor.

12. Plate lifting device

The unit consists of two cylinders that can be set to different positions depending on the length of the sheet.

When the sheet moves to the front of the oblique shear, after stopping, this device will raise the sheet, so that the sheet is clamped on the trolley and moved forward.

13. The oblique shearing machine adopts the principle of rolling shearing to obliquely shear the double-sheared steel plate to obtain the required inclination before bending the street lamp pole plate.

It adopts the structure of upper and lower 2 oblique shearing rolls, power pinch roll and 2 blades. The upper and lower 2 rolls are threaded, which is convenient to adjust the position of rolling shear.

With motor, gear box.

14. discharge row

Suitable for the customer's required length of street lamp pole sheet, row by the ball bearing, and support frame composition.

15. Automatic unloading and stacking of trapezoidal plates

There are two pneumatic clamping feeding rollers after the skew shear, which are used to send the trapezoidal plate away from the skew shear. The lower roller is driven by motor with pneumatic clutch. When the sheet stops moving, the upper roller rises to give the discharge space.

Below the discharge row are 12 sets of pneumatic dischargers that rise from the middle of the table to form two ramps that slide the two trapezoidal plates toward the stacking shelves on either side. Complete automatic unloading and stacking.

All actions are controlled by PLC program and completed automatically.

16. electric control system

Electrical control system: power control console, programmable control system. It contains a frequency converter to control the moving speed of the trolley.

17. The hydraulic system is composed of hydraulic station and corresponding valves, pipelines and cylinders

18. pneumatic system

Clutch for trolley, row, sheet lifting and blanking system.

19. Spare parts for steel plate slitting machine

| No. | Item | Quantity | Remarks |

| 1 | Balde | 2 | |

| 2 | Round ball for feeding | 30 | |

| 3 | 206 bearing seat | 6 | |

| 4 | bearing (NUP2307) | 4 | |

| small bearing | 5 | ||

| 5 | pneumatic pipe 8mm&10mm | 50m、20m | |

| 6 | fitting all kinds of 8mm and 10mm connectors, various connectors | 10 | |

| 7 | MAL32X25 Pnematic cylinder | 3 | |

| 8 | Gear and chain | 3 | |

| 9 | chain wheel | 3 | |

| 10 | 3 toothed chain wheel | 3 | |

| 11 | Chain | 4.5m | |

| 12 | Complete joint and half joint for chain | 10 | |

| 13 | Solenoid vavle | 2 | |

| 14 | Limit switch | 8 | |

| 15 | Megnatic gauge seat | 6 | |

| 16 | feeler | 1 | |

| 17 | Seal belt | 1 | |

| 18 | Cable fastener | 1 |

quadruple leveler

苏ICP备17067978号-1

苏ICP备17067978号-1