CNC Tandem Hydraulic Press Brake

Current position: Home

>

Product

Double-machine linkage electro-hydraulic synchronous numerical control sheet bending machine

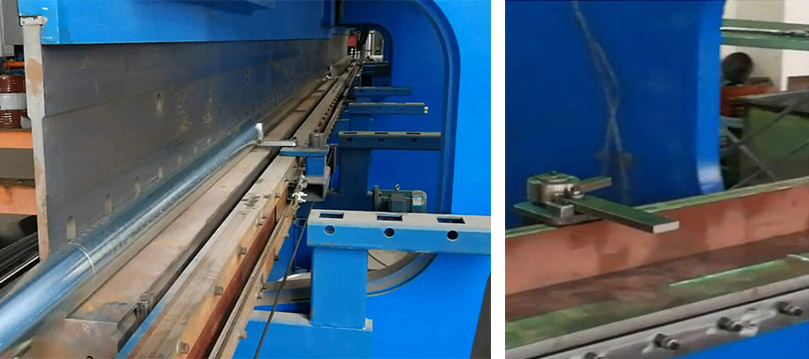

Equipment model: 2-WE67K-400/6000

Application: Street light pole, high pole light pole, monitoring pole, sign pole production

| 1 | working pressure | 2X400Ton(total working pressure 800 tons) | ||||||

| 2 | Table length | 2x6000mm(Total length 12 m) | 2x7000mm(Total length 14 m) | 2x8000mm(Total length 16 m) | ||||

| 3 | panel spacing | 4800mm | 5600mm | 6000mm | ||||

| 4 | Growl depth (designed according to rod diameter) | 720mm | 1000mm | |||||

| 5 | opening height | 950mm | ||||||

| 6 | trip | 250mm | ||||||

| 7 | working speed | Get off | 70mm/s | |||||

| Gongjin | 7mm/s | |||||||

| return trip | 75mm/s | |||||||

| 8 | main motor | 2x30kw | ||||||

| 9 | CNC system | DELEM DA52S DELEM Co., Netherlands2 (Y1,Y2)+ table compensation system | ||||||

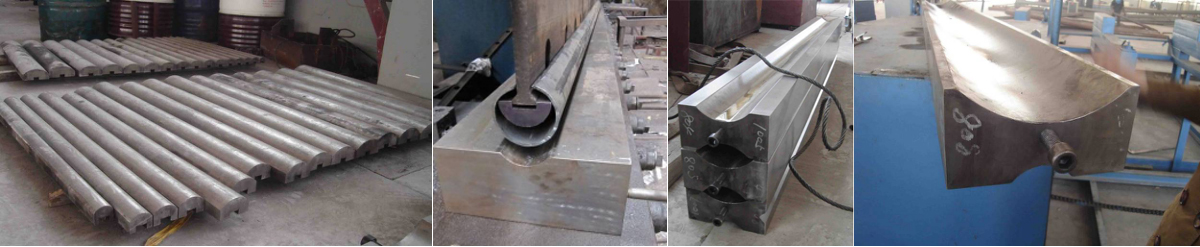

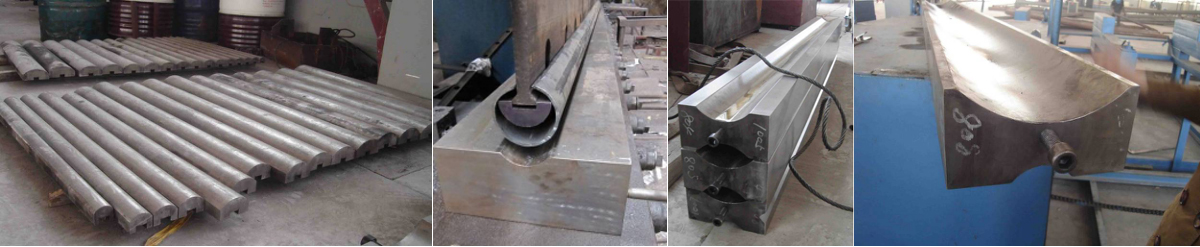

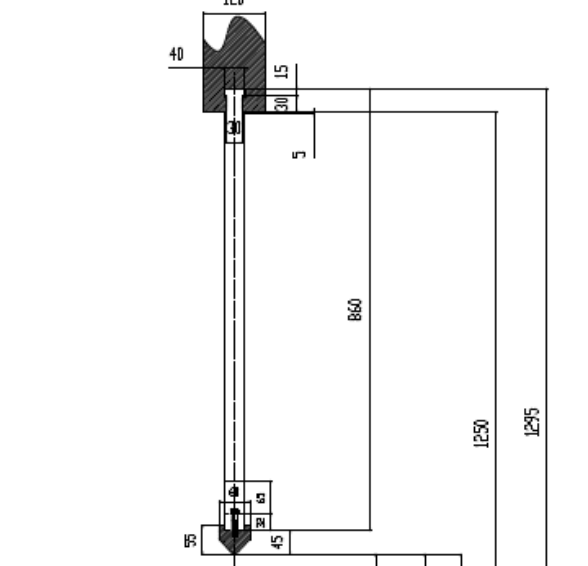

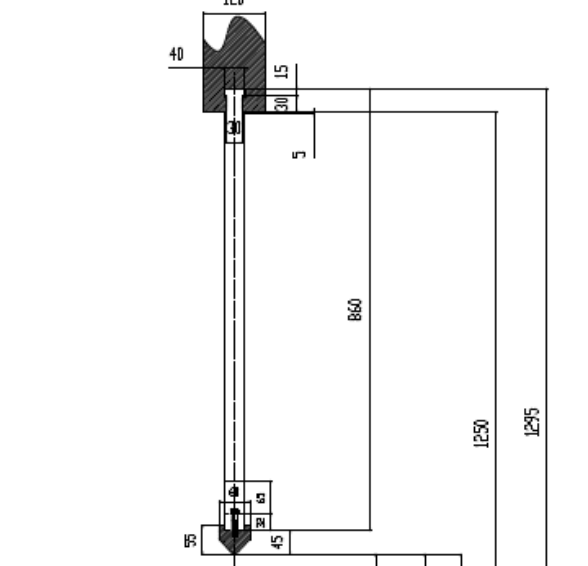

| 10 | die | a die plate, the thickness of which is 18mm, an upper triangular die head R2, | ||||||

| 11 | cylinder seal ring | NOK or SKF type | ||||||

| 12 | hydraulic system | BOSCH-Rexroth, German brand | ||||||

| 13 | hydraulic pump | Sunny, American brand | ||||||

| 14 | grating scale | Fagor, the Spanish brand | ||||||

| 15 | Main electrical components | Schneider | ||||||

| 16 | Net weight of machine | 2x46000 kg | 2x50000 kg | 2x55000 kg | ||||

| 17 | Machine size (L×W×H) | 2x6200x3065x4832 | 2x7200x3065x4832 | 2x8200x3065x4832 | ||||

| 18 | Option 1 | 7-knife forming double-slope cone lamp pole combination die, segmented 11/1000 (diameter 60~214), 13/1000 (diameter 60~242), length 14 meters, cone rod thickness 3~4mm | ||||||

| 19 | Option 2 | 5-knife rapid molding mold 16 meters double slope cone lamp pole mold 11/1000 (diameter 60~236), 13/1000 (diameter 60~268), cone rod thickness 3~4mm | ||||||

| 20 | Option 3 | A socket template with thickness of 40 and length suitable for the machine. Used for high pole lamp, sign pole and electric pole with large thickness. | ||||||

| 21 | Option 4 | Upper triangle die R8, length to fit machine. Used for high pole lamp, sign pole and electric pole with large thickness. | ||||||

| 22 | Option 5 | A set of multi-slot lower dies suitable for the length of the workpiece, for bending octagonal rods, etc. | ||||||

| 23 | Option 6 | Cone upper die reinforcement, 7 m, for cone die head | ||||||

| 24 | Option 7 | Quick push-out type side discharge | ||||||

I. Main technical parameters of the machine:

Y1, Y2 axis-Grating scales (Y1, Y2) on both sides of the slider control the numerical control axis of the cylinders on both sides.

Deflection compensation mechanism of V-axis and worktable

Slide positioning accuracy ±0.02mm

Slide repeated positioning accuracy ±0.01mm

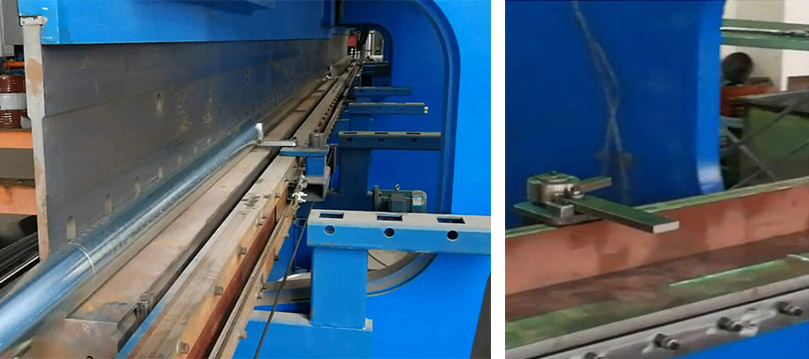

Second, the main performance and characteristics of electro-hydraulic synchronous CNC bending machine:

1. The frame is composed of oil tank, tray, support block, workbench, left and right wallboard and slider, which ensures the structural strength of the frame, and adopts vibration stress relief method, and the surface is sandblasted.

2, machine tool synchronization principle: the application of electro-hydraulic servo proportional valve to ensure dual-machine synchronization, the use of BoschRexroth company's electro-hydraulic servo proportional valve, its performance characteristics are with high control force continuous action electromagnet, mechanical motion pair in the friction is very small and has a fast working characteristics of precision electronic amplifier. A grating ruler is respectively arranged at both ends of the main board of the worktable, the stroke position and the synchronous error of the sliding block are continuously reflected, and the two difference values are sent into a numerical control system to control the electro-hydraulic servo proportional valve so that the single machine and the double cylinders are synchronized. Because the grating ruler is not directly arranged on the frame wallboard but is arranged on the C-shaped frame fixed on the main board of the workbench, and the workbench is taken as a reference point, the deformation of the slide block and the frame under load does not affect the measurement and control precision of the grating ruler. When the two machines are linked, the synchronization information of the two machines is changed into an electric signal and transmitted to the synchronization board and the control system through the differential potentiometer installed between the two sliders, and the electro-hydraulic servo proportional valve is controlled by the Bosch Rexroth amplifier board to make the two machines operate synchronously.

3, DELEM CNC system can automatically calculate and adjust the bending force. It can automatically calculate and control the top dead point and the speed change point. The repeated positioning accuracy of the machine is within ±0.01mm. The slider stroke (Y1, Y2) can make the slider moderately inclined to meet the special needs of users.

4. High-precision guiding system, position measuring system and hydraulic balance function can meet the needs of full-length or eccentric machining.

5. The machine is equipped with a high-precision worktable deflection compensation mechanism to compensate for the deflection generated during work and ensure the bending angle accuracy of each point of the workpiece.

6. The surface of the cylinder plunger is plated with hard chromium, and the cylinder plunger has good self-lubrication, which can greatly improve the service life.

7. The oil cylinder processing adopts the whole forging-rough machining-finish machining-inner wall grinding-inner wall rolling process, so that the inner wall of the oil cylinder has both hardness and wear resistance and high cylindricity precision.

8, with, with motorized side discharge device. (Optional)

9, with a movable foot switch, easy to operate, with emergency power function.

10. The hydraulic control system is imported from BoschRexroth, Germany, and the cylinder seals are imported from Japan NOK or SKF seals.

11. The computer adopts the DA52S system of the Dutch DELEM company, which has complete functions, such as programming, inching, pressure keeping, slow recovery control, etc.

12. The machine tool can work continuously under rated load, while the hydraulic system has no leakage and the work is stable and stable.

13. The hydraulic system has overload overflow safety protection and filter screen blockage alarm display. Our company's hydraulic system oil tank, the use of low heat dissipation good design, to ensure that the oil temperature operation in the appropriate range.

Third, the machine processing capacity: the general cone, octagonal, hexagonal street lamp pole, high pole light pole, power pole

IV. Main Configuration List:

| Serial Number | Name | Brands | Place of Origin and Company |

| pump block | |||

| 1 | valve block | Alpha | China Alpha |

| 2 | cartridge valve | REXROTH | Germany BoschRexroth |

| 3 | Cartridge valve cover plate | Alpha | China Alpha |

| 4 | proportional pressure valve | REXROTH | Germany BoschRexroth |

| 5 | pressure valve | REXROTH | Germany BoschRexroth |

| 6 | electromagnetic directional valve | REXROTH | Germany BoschRexroth |

| synchronization block | |||

| 7 | valve block | Alpha | China Alpha |

| 8 | proportional servo valve | REXROTH | Germany BoschRexroth |

| 9 | cartridge valve | REXROTH | Germany BoschRexroth |

| Other | |||

| 10 | internal gear pump | NACHI | Germany BoschRexroth |

| 11 | sealing ring | NOK or SKF form | NOK or SKF form |

| 12 | guide ring | NOK or SKF form | NOK or SKF form |

| 13 | dust ring | NOK or SKF form | NOK or SKF form |

| 14 | main motor | SIEMENS | Siemens German brand, made in China |

| control system | |||

| 15 | CNC system | Delem | Netherlands Delem(DA-52) |

| 16 | grating scale | Fagor | Spain Fagor |

| 17 | push button | Schneider | French brand, made in China |

V. Accessories

1) One set of O-ring

2) Technical data

Installation foundation diagram, equipment electrical diagram, hydraulic schematic diagram, product specification, product certificate

Six, equipment working environment:-5°-- +40°

VII. Equipment noise standard:≤88dB

VIII. Acceptance

1. Acceptance method: After the equipment is completed by the supplier, the buyer will send personnel to the supplier for pre-acceptance of the equipment, and the final acceptance of the equipment will be carried out after the installation and commissioning of the buyer. The test materials will be provided by the buyer.

2. Acceptance criteria:

1), JB/T2257.1-92 "sheet metal bending machine technical conditions"

2), GB/T14349--93 "precision of sheet metal bending machine"

IX. Delivery, Transportation and Unloading

The equipment shall be dismantled and transported by truck. Waterproof soft packing, in line with the requirements of motor transport, packaging is not recycled. Demander's site unloading fee shall be borne by Demander.

Part V: Equipment Installation and Commissioning

The Supplier shall provide the installation and commissioning services of the machine free of charge, and the Purchaser shall provide the necessary hoisting equipment and a number of auxiliary workers.

X. After-sales service and operator training

1. The operator and maintenance personnel of the demander can come to the supplier to familiarize themselves with the assembly process of the machine tool during the equipment assembly and commissioning stage, and the supplier will transfer professional technicians to provide technical training for the operator of the demander. After the equipment is debugged by the demander, the technical personnel of the supplier shall conduct technical training for the operators of the demander again.

2. The equipment warranty period is one year. In case of equipment failure within one year, the Supplier shall be responsible for maintenance and replacement of spare parts free of charge (except for accidental damage caused by violation of operating procedures by the Purchaser).

3, the supplier to provide equipment lifetime maintenance services.

4. If the machine fails, the supplier shall provide remote service immediately. If necessary, the supplier shall send personnel to the buyer's site within 24 hours.

5. My company's staff, long-term engaged in the production of street lamp pole equipment, and to customers debugging, has accumulated a lot of experience, to provide customers with production process guidance.

Option 1

Conical street lamp pole mould with double taper:

The taper is 11/1000 and 12.5/1000. The total length of the mould is 16 meters. Small diameter 60mm

Option 2

Discharge device, simple wire rope pull-out type

Option 3

Discharge device, electric push-out type

Option 4

Thickness: 40mm, one set of upper connecting template and upper mould, suitable for bending of thick plate high pole light pole and electric power pole

Option 5

Front and rear automatic pushing system for thick plate

苏ICP备17067978号-1

苏ICP备17067978号-1