Steel Plate Slitting Machine For Light Pole

Current position: Home

>

Product

Slitting and slitting production line

1. Application description: steel coil feeding, unwinding, slitting, winding and unloading

2. Technical parameters:

2.1. Raw material thickness: 1.6~4.5mm, yield strength 700~850 high-strength alloy steel, hot-rolled steel, special high-strength steel plate suitable for customers for barrier plate.

Based on the number of cuts: 3, 4 knives cut at the same time.

2.2 Material width: 800-1550mm

2.3 steel coil weight: 30 tons

2.4 Inner diameter of steel coil: 508mm-760mm

2.5 steel coil outer diameter: 1800mm

2.6 Clamping roller diameter: 190mm

2.7 Clamping roller motor power: 2.2kw, gearbox model: BWD13, rate: 187

2.8 Clamping roller working speed: 3m/min

2.9 Number of rough leveling rollers: 3, upper 1 + lower 2.

2.10 Diameter of rough leveling roll: 125mm

2.11 Slitting shaft diameter: 230mm

2.12 Slitting tool shaft material: 40Cr

2.13 Slitting blade diameter: 350

2.14 Slitting blade material: H13K, hardness HRC55-58 (not included in the total price)

2.15 Slitting Main motor power: 45kw (960RPM), gearbox: 650

2.16 Blades, spacers, rubber rings, configured according to customer requirements, are not included in the price of the machine.

2.17 finished slit, slitting width tolerance: ±0.20mm

2.18 finished slit, steel coil weight: 15 tons

2.19 slitting finished product, steel coil inner diameter: 760mm

2.20 slitting buffer pit size: 5500×2200mm×2500mm length× width × depth

2.21 winder main motor power: 90kw (960rpm), gearbox: 850

2.22 winding typical speed, thickness 2.5mm, 25m/min AC frequency adjustable

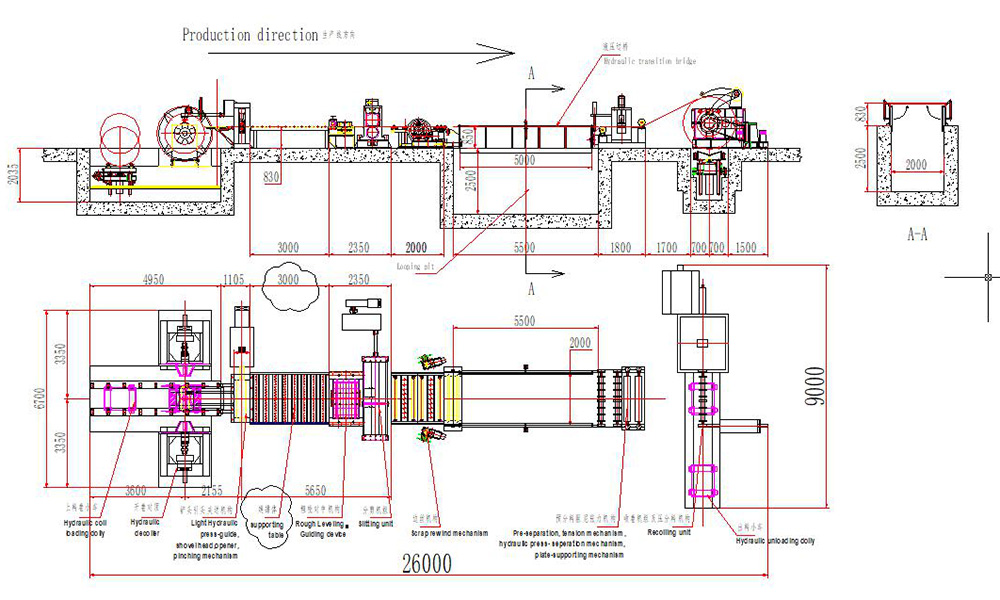

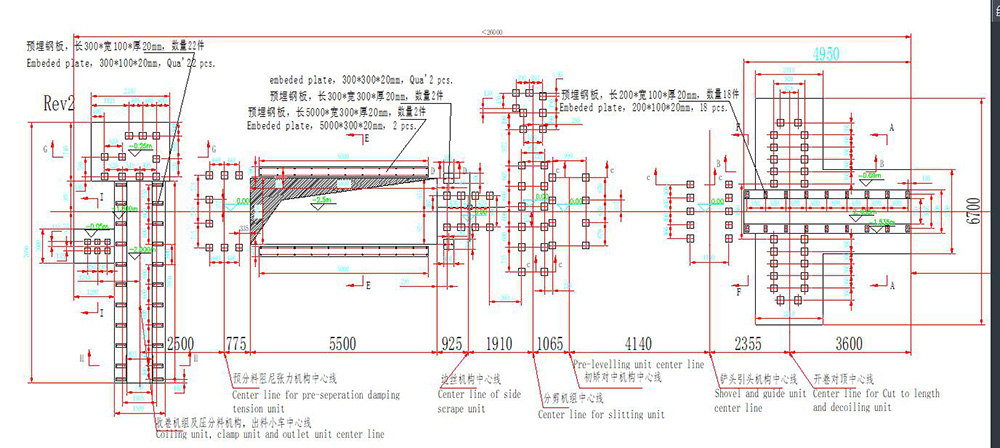

2.23 Detailed foundation and footprint dimensions as shown in the accompanying drawings

2.24 The machine is equipped with a head shearing machine 8mm (Q235), the blade is suitable for the above high strength steel

3 The machine configuration is as follows:

3.1 Hydraulic feeding trolley

The trolley can carry a steel coil so that it moves up and down. The four-wheel guide wheel walking, rising and descending are driven by hydraulic cylinders, and the operation of the trolley is completed by the motor and reducer.

3.2 Hydraulic uncoiling machine

Hydraulic top type uncoiler, including: left and right parts

Hydraulic top tightening, driven by cylinders to the opposite uncoiling frame, can top the coil

It consists of a rail type base, bracket, open reel and hydraulic top type open reel.

The open roll head can be moved left and right and centered at the same time

Equipped with pneumatic brake tension device, during operation, to provide tension to the coil and avoid loose span of the coil

3.3 Indenter, lead, shovelhead, stripping, priming device

It is composed of frame type base, hydraulic guide arm, hydraulic indenter-head mechanism, hydraulic shovelhead mechanism, hydraulic stripping mechanism, hydraulic clamping mechanism, etc.

3.3.1 Hydraulic indenter, lead mechanism: composed of hydraulic guide arm, pressure steel core rubber wheel, sprocket and chain transmission mechanism, equipped with 5.5Kw cycloid pinwheel geared motor, etc. The function is to press the steel coil and drive the steel coil to rotate, which is convenient for shovel head and stripping head.

3.3.2 Hydraulic shovelhead mechanism: It is composed of shovelhead shell, hydraulic shovel head, shovelhead hydraulic lifting & balancing mechanism, etc. Adjust the end of the cylinder so that the shovelhead enters the position of the steel plate head.

3.3.3 Hydraulic stripping head mechanism: It is composed of guide column and guide sleeve, hydraulic stripping head pressing down & lifting mechanism, etc. The function is to straighten the steel plate head, which is convenient for the steel plate head to enter the clamping.

3.3.4 Hydraulic clamping mechanism: by bracket, slider base, 2 clamping rollers, the upper roller hydraulic lifting, the lower stick fixed, the lower roller connected with power, including motor, reducer, clutch. The function of this mechanism is to clamp the steel plate head, pull the plate head, drive the entire steel coil to rotate, and make the plate head enter the rough calibration and slitting machine of the back road.

3.4 head shearing machine: hydraulic 8mm guillotine shearing machine; It is used for shearing the head and tail of the coil and shearing the coil

3.5 Workbench, supporting sheets

3.6 Rough leveling device

It shares a base with the guide before slitting.

For the lower 2 rollers and the upper 1 roller structure, rough leveling roller, passive type. The rough leveling of the sheet metal is conducive to the slitting process of the sheet.

The spacing between the upper and lower rollers is mechanically adjustable.

3.7 Guide before slitting

The guiding device is composed of working bracket, guide rail, screw adjustment and alignment mechanism, active guide base platform, vertical roller mechanism, etc

3.8 Slitting unit:

It consists of a main engine part and power.

Power part: It is composed of power base, reducer, AC variable frequency speed regulating motor, gear distribution box, coupling, clutch, connector, universal cross drive, etc.

Main machine part: by base, fixed bracket, knife shaft large slider, 2 knife shafts, active bracket, knife shaft slider, active bracket hydraulic in and out of the tool changing adjustment mechanism, upper knife shaft electric lifting & pressure adjustable.

The design electrically pushes out the single-sided support bracket, allowing the shaft cantilever to extend for easy replacement of the adjustment blade.

3.9 Edge Threading Mechanism:

It is composed of bracket, side wire shaft, bearing seat, 2 side wire discs, sprocket and sprocket drive mechanism, reducer, coupling, motor, etc. The design of the side wire reel is convenient to undo the side wire roll, and the reserve is large.

3.10 Buffer Pit & Transition Bridge:

It is composed of bracket, bearing seat, support plate,

Length× width × depth: see technical data

Transition table, cylinders as lifting power

It consists of two parts, left and right, which, when closed, facilitate the head from the slitting to the winder

When opened, the sheet metal can enter the buffer pit, which is convenient to adjust the speed difference between winding and slitting, as well as the length difference caused by the different stresses in each steel bar, so that the winding is smooth and the tension is uniform.

3.11 Separation & sizing device, plate support mechanism:

It consists of base, bearing housing, pre-release bearing shaft, damping bracket, damping plate, damping plate hydraulic lifting & pressing down mechanism, tension bracket, 2 tension rollers, steel bar separation & tension bracket, separation & surge shaft, hydraulic pressure down & lifting mechanism, hydraulic support mechanism, equipped with separation plate, nylon gasket, etc.

The damping plate hydraulic lifting & pressing mechanism is provided with a synchronous mechanical structure of the left and right tooth shafts. Make sure that the sheet metal tension on the left and right is consistent.

3.12 Winding device

It consists of machine base, winding gearbox, hydraulic expansion and contraction winding mandrel system, tensioning plate, diagonal wedge slide rising and shrinking mechanism, expansion rotary cylinder mechanism, driving mechanism.

Drive mechanism, including frequency conversion speed control motor, belt, pulley, etc

Equipped with hydraulically adjustable diaphragm shaft

Swivel side support arm to support the base.

3.13 Hydraulic discharge trolley:

The width of the trolley and the width of the coil are consistent, can be hydraulically lifted, can run left and right, the function is to carry the steel coil after slitting, move out, convenient for the workshop, lift away the steel coil, the trolley runs left and right by the motor drive.

3.14 Electrical systems:

Center console.

It is composed of electric cabinet, main electronic control operation cabinet, auxiliary operation cabinet and other electrical equipment, slitting and winding motor.

The equipment is equipped with safety protection devices, with emergency stop and power cut off buttons, machine stop display lights, etc.

3.15 Hydraulic systems:

Hydraulic power 25L/min

Including: hydraulic station, valve, oil tank, fitting, hose, hard pipe, etc.

3.16 Pneumatic system: including cylinder, air pipe, joint, pneumatic valve, etc

3.17 Blades, spacer rings, rubber rings, configured according to customer requirements, are not included in the price of the machine.

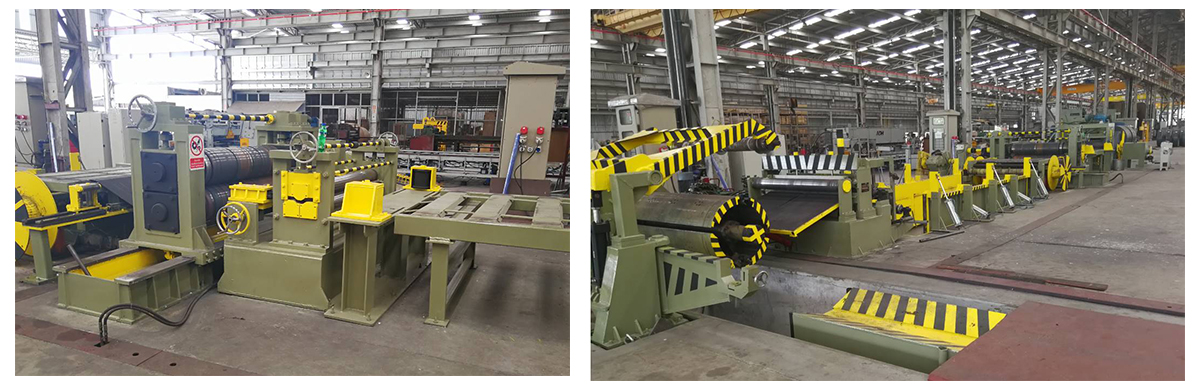

4. Drawings: equipment layout drawing (size for reference), equipment picture

苏ICP备17067978号-1

苏ICP备17067978号-1