Cut To Length Line For Light Pole

Current position: Home

>

Product

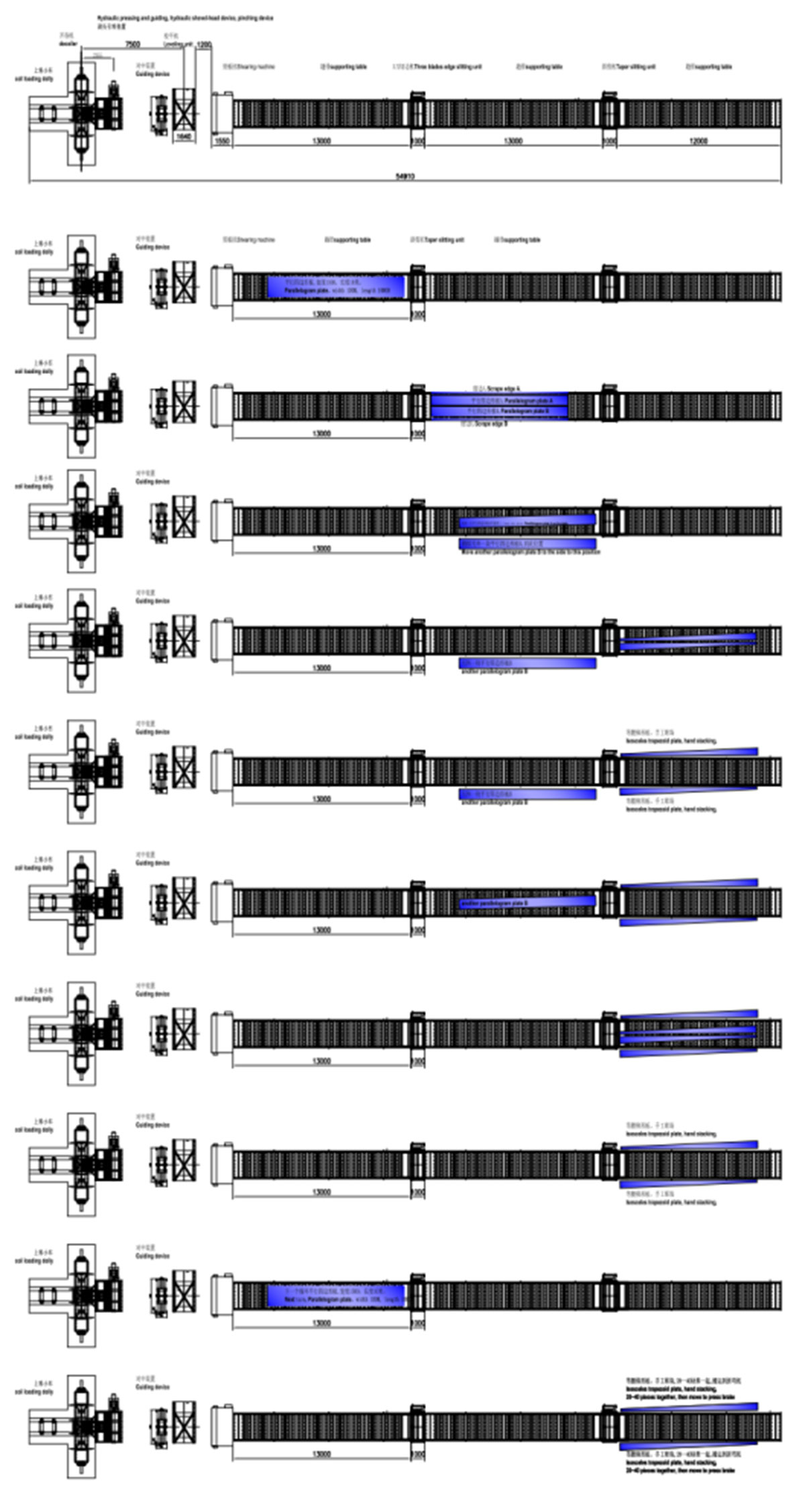

Cut to length line for light pole, model: CTLA6x1600 Automatic type,With two lay type leveling machine+ shearing + 3 blades edge slitting + taper slitting unit.

Proprietary features:

1.The raw material is steel coil, and the output is isosceles trapezoidal plate suitable for the size of street light pole

2.Uncoiling, leveling, length cutting, edge removal, oblique shearing, unlading and stacking in one production line. It is a machine and a process. After the plate shears cross cut, there is no need to drive the crane for loading and unloading, and directly enter the oblique shear process. Reduce the number of operators, labor and improve the production speed.

3.Full automatic type, sheet length CNC control, sheet quantity CNC control, automatic oblique shear, automatic unloading and automatic stacking system.

4.The production speed is extremely fast, because the speed is far faster than the subsequent process. Generally, after this process is completed, the operators can work in other processes, which greatly saves working time and reduces production costs.

5.The operator shall be relaxed and minimize contact with the steel plate, which is safe for personnel.

6.The shearing machine has the function of overall rotation, which can rotate at a certain angle relative to the center line, so that the cut plate is parallelogram, which is convenient for the oblique shearing machine to obtain isosceles trapezoid plate after oblique shearing, which is suitable for the production of light pole. There is no need for trimming process to reduce sheet metal waste.

7.Three blade edge cutting device, which can remove the waste edge and cut the middle half at the same time when the sheet width can be used as four poles.

8.After oblique shearing, the plates in the same direction are stacked separately without sorting. Multiple plates (such as 30 plates) can be directly hoisted to the bending machine, which is safe and saves time.

9.The optional leveling unit after taper slitting , which can remove the stress caused by the taper cutting and make high-quality light poles.

2.Uncoiling, leveling, length cutting, edge removal, oblique shearing, unlading and stacking in one production line. It is a machine and a process. After the plate shears cross cut, there is no need to drive the crane for loading and unloading, and directly enter the oblique shear process. Reduce the number of operators, labor and improve the production speed.

3.Full automatic type, sheet length CNC control, sheet quantity CNC control, automatic oblique shear, automatic unloading and automatic stacking system.

4.The production speed is extremely fast, because the speed is far faster than the subsequent process. Generally, after this process is completed, the operators can work in other processes, which greatly saves working time and reduces production costs.

5.The operator shall be relaxed and minimize contact with the steel plate, which is safe for personnel.

6.The shearing machine has the function of overall rotation, which can rotate at a certain angle relative to the center line, so that the cut plate is parallelogram, which is convenient for the oblique shearing machine to obtain isosceles trapezoid plate after oblique shearing, which is suitable for the production of light pole. There is no need for trimming process to reduce sheet metal waste.

7.Three blade edge cutting device, which can remove the waste edge and cut the middle half at the same time when the sheet width can be used as four poles.

8.After oblique shearing, the plates in the same direction are stacked separately without sorting. Multiple plates (such as 30 plates) can be directly hoisted to the bending machine, which is safe and saves time.

9.The optional leveling unit after taper slitting , which can remove the stress caused by the taper cutting and make high-quality light poles.

Application:

It is for light pole material uncoiling, leveling, cutting, scrape edge slitting and taper slitting process, to get one side small width, one side big width steel plate.

It is for light pole material uncoiling, leveling, cutting, scrape edge slitting and taper slitting process, to get one side small width, one side big width steel plate.

Technical Parameter and Composed Devices

Technical Parameter

1.Thickness of material:hot rolled mild steel

Max:6mm, Min: 2mm for Q235,Q345 , yield strength:235Mpa,345Mpa

2.Max width of steel plate:1600mm

3.Weight of steel coil:Max 30 tons

4.Inner diameter of steel coil:Φ508mm-Φ760mm

5.Leveling speed:5- 15m/min

6.Number of leveling rollers: 11

7.Leveling rollers diameter : 132mm

8.Leveling roller distance: 143mm

9.Leveling roller material: 40Cr

10.Leveling roller hardness: HRC55-58

11.Length range for scale:2000~12000mm according requirements

12.Tolerance of cutting length :Tolerance of cutting length :less ±5mm (base on 8m length plate)

13.Main leveling motor power: 37kw, 960RPM

14.Shearing machine capacity: 6mmx2500mm

15.Shearing machine rotation angle :Max. 1.5 degree.

16.double edge and taper Slitting speed : 15 m/min.

17.Power of the main motor for slitting: 5.5kw

18.Dolly moving speed: 15m/min. adjustable

19.Slitting blade material : H13k

20.Slitting blade diameter: 280mm

21.taper slitting Pinching roll diameter:280mm

22.Max. inner Width of edge slitting unit: 1550mm

23.Max. inner Width of taper slitting unit: 1800mm

24.Production speed: 250~400 pieces Isosceles trapezoid plate for street light pole (base on length 6~8m)

25.Operator quantity:1~2

26.width area for machine:about 7200mm

1.Thickness of material:hot rolled mild steel

Max:6mm, Min: 2mm for Q235,Q345 , yield strength:235Mpa,345Mpa

2.Max width of steel plate:1600mm

3.Weight of steel coil:Max 30 tons

4.Inner diameter of steel coil:Φ508mm-Φ760mm

5.Leveling speed:5- 15m/min

6.Number of leveling rollers: 11

7.Leveling rollers diameter : 132mm

8.Leveling roller distance: 143mm

9.Leveling roller material: 40Cr

10.Leveling roller hardness: HRC55-58

11.Length range for scale:2000~12000mm according requirements

12.Tolerance of cutting length :Tolerance of cutting length :less ±5mm (base on 8m length plate)

13.Main leveling motor power: 37kw, 960RPM

14.Shearing machine capacity: 6mmx2500mm

15.Shearing machine rotation angle :Max. 1.5 degree.

16.double edge and taper Slitting speed : 15 m/min.

17.Power of the main motor for slitting: 5.5kw

18.Dolly moving speed: 15m/min. adjustable

19.Slitting blade material : H13k

20.Slitting blade diameter: 280mm

21.taper slitting Pinching roll diameter:280mm

22.Max. inner Width of edge slitting unit: 1550mm

23.Max. inner Width of taper slitting unit: 1800mm

24.Production speed: 250~400 pieces Isosceles trapezoid plate for street light pole (base on length 6~8m)

25.Operator quantity:1~2

26.width area for machine:about 7200mm

Detail of the device

1. Steel coil loading dolly car:

UP and down: Hydraulic

Horizontal moving: motorized

UP and down: Hydraulic

Horizontal moving: motorized

2. Hydraulic double-head umbrella type decoiler:

Including:left and right unit,

Open and close: Hydraulic

The pair of uncoiling frame driven by the oil cylinder, can hold on the coil material.

Structure: machine body, sliding base, main shaft, taper loading tray, moving cylinder.

Main function: fixed steel coil to realize passive uncoiling. Equipped with a set of manual brake device, which can be adjusted according to the coil tension. The lateral stroke is completed by the double-sided moving oil cylinder. The two cylinders in the center can be shifted left and right at the same time by adjusting the width of the coil.

Including:left and right unit,

Open and close: Hydraulic

The pair of uncoiling frame driven by the oil cylinder, can hold on the coil material.

Structure: machine body, sliding base, main shaft, taper loading tray, moving cylinder.

Main function: fixed steel coil to realize passive uncoiling. Equipped with a set of manual brake device, which can be adjusted according to the coil tension. The lateral stroke is completed by the double-sided moving oil cylinder. The two cylinders in the center can be shifted left and right at the same time by adjusting the width of the coil.

3. Hydraulic pressing and guiding, hydraulic shovel-head device, pinching device

Used to shovel the wool of the coil material into the traction. Hydraulic lifting and hydraulic pressing can prevent the roll material from loosening, and working with the stripping head to guide the material into the traction roller. The power traction pulls the sheet material through two nip rollers, and the upper nip roller is hydraulically lifted and lowered.

Structure: lead frame, lead roller, lead motor sprocket, chain, lift cylinder, shovel head support plate, telescopic panel, drive cylinder.

Main functions: auxiliary decoiling , the lead roller is driven by a motor. Help the decoiler to guide the plate head to the shovel board. Then it is led to the feeding nip roller, the shovel plate can be raised and lowered and retracted back and forth. During normal operation, this device will not join the production process.

Pinch feeding structure: It is composed of machine base, archway, slide feed shaft, drive motor, and press down cylinder.

Main function: send the sheet to the rear equipment, and the transmission adopts the motor cycloid reducer and clutch. After the pinch is completed and the sheet material enters the leveling host, the clutch is disengaged, the upper roller is hydraulically lifted, and the lower roller is driven by the sheet material to rotate passively.

Used to shovel the wool of the coil material into the traction. Hydraulic lifting and hydraulic pressing can prevent the roll material from loosening, and working with the stripping head to guide the material into the traction roller. The power traction pulls the sheet material through two nip rollers, and the upper nip roller is hydraulically lifted and lowered.

Structure: lead frame, lead roller, lead motor sprocket, chain, lift cylinder, shovel head support plate, telescopic panel, drive cylinder.

Main functions: auxiliary decoiling , the lead roller is driven by a motor. Help the decoiler to guide the plate head to the shovel board. Then it is led to the feeding nip roller, the shovel plate can be raised and lowered and retracted back and forth. During normal operation, this device will not join the production process.

Pinch feeding structure: It is composed of machine base, archway, slide feed shaft, drive motor, and press down cylinder.

Main function: send the sheet to the rear equipment, and the transmission adopts the motor cycloid reducer and clutch. After the pinch is completed and the sheet material enters the leveling host, the clutch is disengaged, the upper roller is hydraulically lifted, and the lower roller is driven by the sheet material to rotate passively.

4.Middle rolling way worktable:

This device is used to support the plate.

This device is used to support the plate.

5. Guiding device

It is composed of guild frame, moveable plane plate, guiding adjustment device, vertical lean wheel.

It is composed of guild frame, moveable plane plate, guiding adjustment device, vertical lean wheel.

6. Leveling unit:(two lay type)。

It is composed of frame part, work roll part, lifting part and main driving part.

The frame part adopts the steel plate welding structure, and the work roll part, the lifting part and the frame part are organically combined.

The work roll is composed of leveling rolls.

The leveling roller adopts the parallel type of roller rows. The upper roller can move up and down and can be inclined relative to the lower roller. The opening size of the entrance and exit can be adjusted separately to achieve the ideal leveling effect. The material of the leveling roller is surface hardened.

It is composed of frame part, work roll part, lifting part and main driving part.

The frame part adopts the steel plate welding structure, and the work roll part, the lifting part and the frame part are organically combined.

The work roll is composed of leveling rolls.

The leveling roller adopts the parallel type of roller rows. The upper roller can move up and down and can be inclined relative to the lower roller. The opening size of the entrance and exit can be adjusted separately to achieve the ideal leveling effect. The material of the leveling roller is surface hardened.

The main function of the lifting part is to lift the upper row of leveling rollers and adjust the pressing amount between the leveling rollers. The motor of this machine achieves the purpose of lifting the upper row of rollers through the reducer, worm gear and worm drive screw nut.

The main driving part is driven by a variable frequency AC motor through a reducer to drive the leveling roller.

On the discharge side of the leveling machine, an independent encoder pneumatic pressure measuring device is installed. The rotary encoder detects the size of the feeding cut-to-length and cuts and controls it through the electrical system.

The main driving part is driven by a variable frequency AC motor through a reducer to drive the leveling roller.

On the discharge side of the leveling machine, an independent encoder pneumatic pressure measuring device is installed. The rotary encoder detects the size of the feeding cut-to-length and cuts and controls it through the electrical system.

7. Shearing machine:

Shearing machine is a device for cutting the leveled steel plate in the production line.

Machine structure and characteristics description: steel plate welding, high strength, good rigidity, hydraulic up and down tool holder, stable and fast movement. The lower blade has a front and rear fine-tuning mechanism, the knife edge gap uniformity is good, and the cutting straightness accuracy is high. The blade gap adjustment is convenient and quick, the left and right sides are synchronized, and the scale value is indicated. The hydraulic pressure material is stable and gentle, and the pressure foot pad is made of polyurethane material, which does not damage the surface of the workpiece.

The shearing machine has an integral rotation function, which can rotate relative to the center line at a certain angle, so that the cutting sheet is a parallelogram, which is convenient for the taper slitting to obtain an isosceles trapezoidal sheet after oblique cutting, suitable for the production of street light poles.

Shearing machine is a device for cutting the leveled steel plate in the production line.

Machine structure and characteristics description: steel plate welding, high strength, good rigidity, hydraulic up and down tool holder, stable and fast movement. The lower blade has a front and rear fine-tuning mechanism, the knife edge gap uniformity is good, and the cutting straightness accuracy is high. The blade gap adjustment is convenient and quick, the left and right sides are synchronized, and the scale value is indicated. The hydraulic pressure material is stable and gentle, and the pressure foot pad is made of polyurethane material, which does not damage the surface of the workpiece.

The shearing machine has an integral rotation function, which can rotate relative to the center line at a certain angle, so that the cutting sheet is a parallelogram, which is convenient for the taper slitting to obtain an isosceles trapezoidal sheet after oblique cutting, suitable for the production of street light poles.

8. Pole length supporting table + trolly ,with Automation device :

There is a trolly in the front of the edge slitting unit. It is for control the slitting straight and parallelogram plate size. By change the position of the stopper on dolly to control the parallelogram plate size .

The trolly with motorized driving, it can move to the right position on the table according the length of pole plate.

The table roller with motorized driving, when the roller is dived by motor, the plate can move to the slitting unit and no need push the plate manually. Every roller with pneumatic clutch, it can be drove by motor and chain system, also can move the plate manually for adjusting the plate.

Both on trolly and in the front edge slitting unit, there are pneumatic device for push plate to stop to get right dimension of the parallelogram plate.

There is a trolly in the front of the edge slitting unit. It is for control the slitting straight and parallelogram plate size. By change the position of the stopper on dolly to control the parallelogram plate size .

The trolly with motorized driving, it can move to the right position on the table according the length of pole plate.

The table roller with motorized driving, when the roller is dived by motor, the plate can move to the slitting unit and no need push the plate manually. Every roller with pneumatic clutch, it can be drove by motor and chain system, also can move the plate manually for adjusting the plate.

Both on trolly and in the front edge slitting unit, there are pneumatic device for push plate to stop to get right dimension of the parallelogram plate.

9. Plate rising device.

This device includes two pneumatic cylinder, and it can be moved to different location according the plate length.

When the plate reach the front of slitting unit , plate will be stopped, this device will rise the plate , in order that the trolly can clamp and move the plate.

This device includes two pneumatic cylinder, and it can be moved to different location according the plate length.

When the plate reach the front of slitting unit , plate will be stopped, this device will rise the plate , in order that the trolly can clamp and move the plate.

10.Three blades edge slitting unit.

The edge slitting machine is base on the rolling shearing principle to cut the steel sheet.

It is for slitting scrape edge of the parallelogram steel plate to get the exact width for light pole.

If the plate width suitable for four pieces pole, the middle blade can cut the plate to two big pieces.

Including : two pairs pinching rollers, Motor, gear box, four blades

Up and down two screw type rollers, with 3 pairs of slitting blade.

screw type rollers is easy for adjusting the cutting blade to any position for slitting any size of plate.

The edge slitting machine is base on the rolling shearing principle to cut the steel sheet.

It is for slitting scrape edge of the parallelogram steel plate to get the exact width for light pole.

If the plate width suitable for four pieces pole, the middle blade can cut the plate to two big pieces.

Including : two pairs pinching rollers, Motor, gear box, four blades

Up and down two screw type rollers, with 3 pairs of slitting blade.

screw type rollers is easy for adjusting the cutting blade to any position for slitting any size of plate.

11.Pole length supporting table + trolly ,with Automation device :

There is a dolly in the front of the slitting unit. It is for control the taper cutting degree. By change the position of the stopper on dolly to control the taper slitting rate.

The dolly with motorized driving, it can move to the right position on the table according the length of pole plate. And clamp the plate to get right plate moving direction.

The table roller with motorized driving, when the roller is dived by motor, the plate can move to the slitting unit and no need push the plate manually. Every roller with pneumatic clutch, it can be drove by motor and chain system, also can move the plate manually for adjusting the plate.

Both on dolly and in the front taper slitting unit, there are pneumatic devices for push plate to stop to get right taper cutting angle.

There is a dolly in the front of the slitting unit. It is for control the taper cutting degree. By change the position of the stopper on dolly to control the taper slitting rate.

The dolly with motorized driving, it can move to the right position on the table according the length of pole plate. And clamp the plate to get right plate moving direction.

The table roller with motorized driving, when the roller is dived by motor, the plate can move to the slitting unit and no need push the plate manually. Every roller with pneumatic clutch, it can be drove by motor and chain system, also can move the plate manually for adjusting the plate.

Both on dolly and in the front taper slitting unit, there are pneumatic devices for push plate to stop to get right taper cutting angle.

12. Plate rising device.

This device includes two pneumatic cylinder, and it can be moved to different location according the plate length.

When the plate reach the front of slitting unit , plate will be stopped, this device will rise the plate , in order that the dolly can clamp and move the plate.

This device includes two pneumatic cylinder, and it can be moved to different location according the plate length.

When the plate reach the front of slitting unit , plate will be stopped, this device will rise the plate , in order that the dolly can clamp and move the plate.

13. Taper slitting unit

The taper slitting machine is base on the rolling shearing principle to cut the steel sheet. And get trapezium plate with certain taper rate.

Including : two pairs pinching rollers, Motor, gear box, up and bottom pinching rollers, two blades,

Up and down two screw type rollers, with one pairs of slitting blade.

screw type rollers is easy for adjusting the cutting blade to any position for slitting any size of plate.

The taper slitting machine is base on the rolling shearing principle to cut the steel sheet. And get trapezium plate with certain taper rate.

Including : two pairs pinching rollers, Motor, gear box, up and bottom pinching rollers, two blades,

Up and down two screw type rollers, with one pairs of slitting blade.

screw type rollers is easy for adjusting the cutting blade to any position for slitting any size of plate.

14. Ball type support table for unloading

The street light pole sheet material of the length suitable for the customer's needs, the trip row is composed of a ball support and a support frame.

The street light pole sheet material of the length suitable for the customer's needs, the trip row is composed of a ball support and a support frame.

15. Taper plate unloading and stacking automatic system

There are two pneumatic pinching rollers. The bottom pinching roller is with motorized driving, when the roller is dived by motor, the taper plate can move to far away from slitting unit. When the plate stopped moving, the up roller will rise and give the space for unloading the plate.

Under the table , this are 12 units pneumatic unloading device. They can rise from the middle of table, then two pieces taper plate will slide to both side stacking stand.

There are two pneumatic pinching rollers. The bottom pinching roller is with motorized driving, when the roller is dived by motor, the taper plate can move to far away from slitting unit. When the plate stopped moving, the up roller will rise and give the space for unloading the plate.

Under the table , this are 12 units pneumatic unloading device. They can rise from the middle of table, then two pieces taper plate will slide to both side stacking stand.

16. Electrical system:

Central control table.

For double edge slitting and taper slitting, also PLC, AC driver inverter have the feature of quick response and good activity,which can effectively control the dolly running speed.

Central control table.

For double edge slitting and taper slitting, also PLC, AC driver inverter have the feature of quick response and good activity,which can effectively control the dolly running speed.

17 Hydraulic system:

Hydraulic power station

Including:hydraulic station, valves, oil tank, joint, soft pipe, hard pipe and so on.

Hydraulic power station

Including:hydraulic station, valves, oil tank, joint, soft pipe, hard pipe and so on.

18. Pneumatic system:

For dolly and table clutch, plate rising ,plate unloading device etc.

For dolly and table clutch, plate rising ,plate unloading device etc.

19.Options:

Option 1: Four lay type leveling unit, better leveling result, release stress

This is the core equipment of this line which divided into power part and host part.

Power part is composed of power stand, decelerator, AC speed adjustable motor, AC electric cabinet(AC frequency motor driver), coupling, power distributing case, strap wheel, strap, universal joint and YWZ brake, etc.

Host part is composed of bottom-stand, frame, under axle stand, sliding axle stand, leveling roller, upper supporting frame, up-and-down supporting wheel stand, supporting wheel, electric lifting and pressing device, accompany of 2 pcs of pressing motor, manual lubricate pump.

Characteristic of this machine:

It adopted power distributing case, each leveling roller are connected with universal cross coupling, up-and-down leveling roller are both active, linear speed is consistence, so the frictions between roller surface and plate will decrease, which could prompt leveling efficiency.

There are two sets of roller bearing on both sides of leveling axle, one set of plane pushing bearing used to decreasing the frictions and prevent axial from librating, which could prompt efficiency.

Two groups of supporting wheel is installed on the machine in which could adjust up-and down, front-and back sides. It used to support the main roller and increase roller hardness and prompt leveling efficiency. Bearing on supporting wheel is sealed which could prevent oxide slag entering into bearing.

The machine is adopt worm gear and worm rod, large torsion on adjusting bipolar decelerating and pressing, heavy pressing power, it could adjusted individually and synchronously to lifting and pressing down, and set manual micro-adjustment.

Leveling roller is mid frequency induction quenching, deeper level, which could avoid burning the bearing when short of oil and could longer the machine life.

Leveling host machine is adopt centralized oil supply which could operating easily. Major components are vibrating by advanced vibrator in homeland which could demolishing stress and reducing bending. Motor is direct-current speed adjustable motor, accompany of Eurotherm core plate which could reducing lifting and braking time(two thirds brake times shorter than common ones) and prompt leveling efficiency.

Option 1: Four lay type leveling unit, better leveling result, release stress

This is the core equipment of this line which divided into power part and host part.

Power part is composed of power stand, decelerator, AC speed adjustable motor, AC electric cabinet(AC frequency motor driver), coupling, power distributing case, strap wheel, strap, universal joint and YWZ brake, etc.

Host part is composed of bottom-stand, frame, under axle stand, sliding axle stand, leveling roller, upper supporting frame, up-and-down supporting wheel stand, supporting wheel, electric lifting and pressing device, accompany of 2 pcs of pressing motor, manual lubricate pump.

Characteristic of this machine:

It adopted power distributing case, each leveling roller are connected with universal cross coupling, up-and-down leveling roller are both active, linear speed is consistence, so the frictions between roller surface and plate will decrease, which could prompt leveling efficiency.

There are two sets of roller bearing on both sides of leveling axle, one set of plane pushing bearing used to decreasing the frictions and prevent axial from librating, which could prompt efficiency.

Two groups of supporting wheel is installed on the machine in which could adjust up-and down, front-and back sides. It used to support the main roller and increase roller hardness and prompt leveling efficiency. Bearing on supporting wheel is sealed which could prevent oxide slag entering into bearing.

The machine is adopt worm gear and worm rod, large torsion on adjusting bipolar decelerating and pressing, heavy pressing power, it could adjusted individually and synchronously to lifting and pressing down, and set manual micro-adjustment.

Leveling roller is mid frequency induction quenching, deeper level, which could avoid burning the bearing when short of oil and could longer the machine life.

Leveling host machine is adopt centralized oil supply which could operating easily. Major components are vibrating by advanced vibrator in homeland which could demolishing stress and reducing bending. Motor is direct-current speed adjustable motor, accompany of Eurotherm core plate which could reducing lifting and braking time(two thirds brake times shorter than common ones) and prompt leveling efficiency.

Option 2:

Leveling machine after taper slitting,

At a position 1 meter behind the taper slitting machine, set a leveling machine to remove the internal stress of the sheet material to obtain a flat street light pole sheet material. Facilitate the straightening of the seam in the next bending process.

7-roller structure, upper 3 lower 4.

Leveling machine after taper slitting,

At a position 1 meter behind the taper slitting machine, set a leveling machine to remove the internal stress of the sheet material to obtain a flat street light pole sheet material. Facilitate the straightening of the seam in the next bending process.

7-roller structure, upper 3 lower 4.

Option 3:Plate offline system

Option4: Spare parts

Option 2: Leveling machine after taper slitting

Option 1: Four lay type leveling unit, better leveling result, release stress

苏ICP备17067978号-1

苏ICP备17067978号-1